Combination Face Frame Assembly and Door Clamping Tables

Ritter’s heavy duty combination face frame assembly and door clamping tables ensure flush and tight joint construction is provided for all types of wood. Screwed together face frame construction provides the most efficient and economical method of joining frames. The elimination of dowel boring and insertion, clamping time and joint misalignment can provide up to 50% time reduction in frame production.

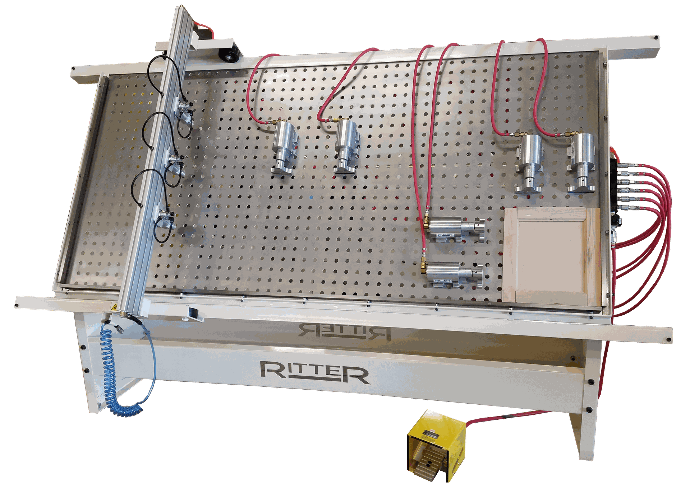

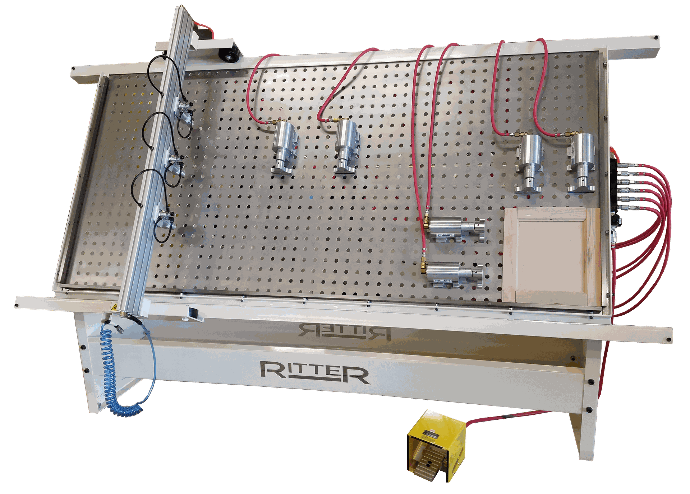

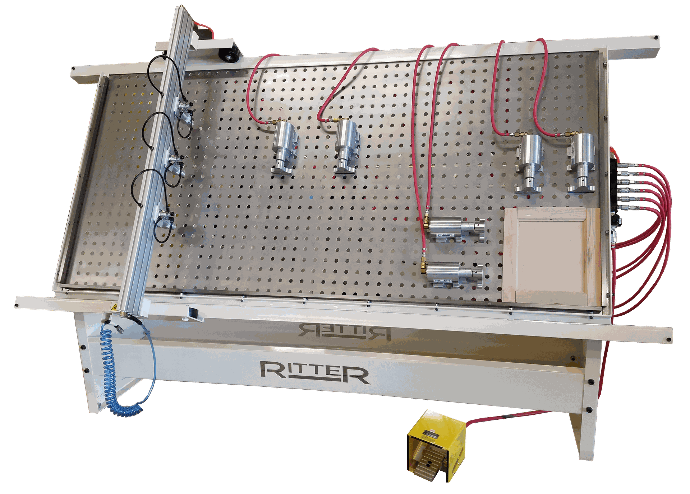

R475EAO

- 3'x6' Assembly Table w/ Open back

- Hold Down Beam with (3) Adjustable Hold Down Cylinders

- Squaring Bars on Left, Right and Bottom Sides

- Usable Table Area: 33.5" x 71"

R275EA

- 4'x8' Assembly Table

- Hold Down Beam with (3) Adjustable Hold Down Cylinders

- Squaring Bars on Left, Right and Bottom Sides

- Usable Table Area: 46" x 95"

R275EAO

- 4'x8' Assembly Table w/ Open back

- Hold Down Beam with (3) Adjustable Hold Down Cylinders

- Squaring Bars on Left, Right and Bottom Sides

- Usable Table Area: 46" x 95"

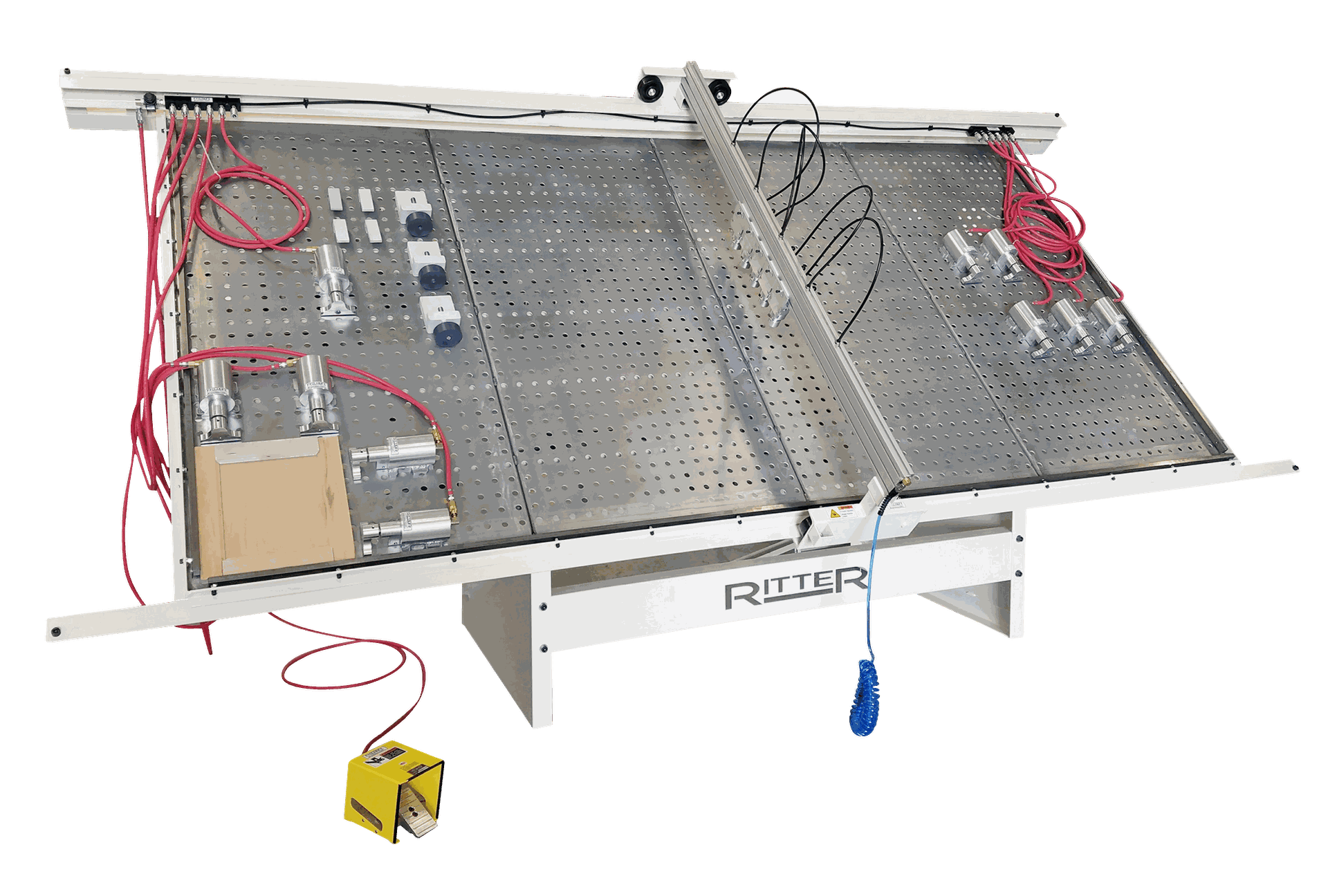

R250EA

- 6'x12' Assembly Table w/ Open back

- Hold Down Beam with (5) Adjustable Hold Down Cylinders

- Squaring Bars on Left, Right and Bottom Sides

- Usable Table Area: 58.5" x 141"

About Ritter's Combination Tables

The Ritter combination face frame assembly and door clamping table line are specifically designed for use in cabinetmaking and woodworking shops and are used for

doweled, mortise and tenon, or screwed together frames and cabinet doors

for cabinets. Ritter's combination face frame assembly and door clamping tables are known for their high quality and durability and are a popular choice among professional woodworkers and cabinet makers.

Our Ritter

combination face frame assembly and door clamping tables

assist you with holding the pieces in place while they are being joined. Our clamp beam provides clamping the material down without adding any adding side clamping pressure. We have tables in a variety of sizes, squaring bars, and other tools to help with the cutting and shaping of the face frame pieces. The goal of a

combination face frame assembly and door clamping table is to make the process of assembling

doweled, mortise and tenon, or screwed together frames and cabinet doors

easier, faster, and more accurate.

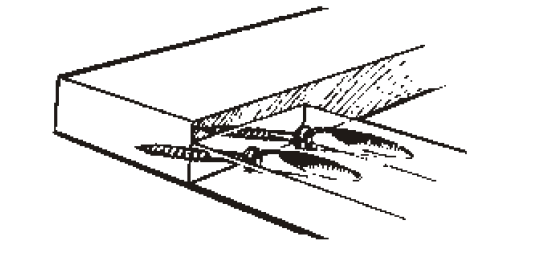

Joint Construction

Material thickness variations do not create misalignment at the face side. This is provided by clamping the material down with the R200A clamp beam. Tight joint construction is provided by the screws being used as the tightening force, not side clamping pressure. The screw angle is adjustable to allow for 5/8” or thicker material.

Need More Information?

Give Ritter Machinery a call today or find your local Ritter Distributor here.