Internal Reference:

R200E/A

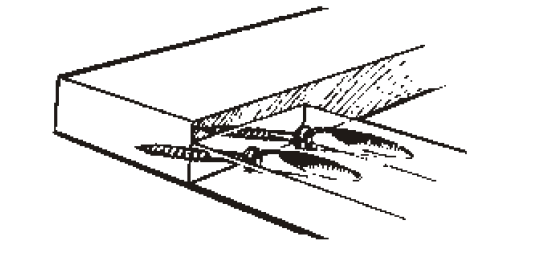

Designed for pocket joinery face frame construction. The R200EA provides the most efficient and economical method of frame joinery. Flush and tight joint construction is provided on all types of wood. The elimination of dowel boring, dowel and glue insertion, clamping time and joint misalignment provides up to 50% reduction in frame construction. The ability to disassemble a frame and reposition a joint without the loss of material adds to the systems productivity. The design of the pocket borer eliminates the need for glue to be applied to the joint.

For the assembly of wooden cabinet face frames. This heavy duty table insures a flat surface, with squaring corners, and a set of pneumatic clamps to secure the frame during assembly. Used in conjunction with a pocket hole cutter, such as the R200T, or the R220T, to create the screw pocket.

Joint Construction

Material thickness variations do not create misalignment at the face side. This is provided by clamping the material down with the R200A clamp beam. Tight joint construction is provided by the screws being used as the tightening force, not side clamping pressure. The screw angle is adjustable to allow for 5/8” or thicker material.

Videos

Need More Information?

Give Ritter Machinery a call today or find your local Ritter Distributor here.